|

|

Principal Products

- AIRTEK

- CENTEC

- DITECO

- DOSCH

- H E - TITAN

- HOFFER Turbine Flowmeter

- IGS

- INOXCVA

- MASTER MAG

- PHE- GEA

- SAIMO

- SODERN

- SYSCO

- TECTRON

- Thermofisher Scientific

Nitrogen Generators

Generon IGS has a unique advantage because we offer both Pressure Swing Adsorption (PSA) and Hollow Fiber Membrane technologies to separate air and gas. We are not biased to either technology, our goal is to match our customer’s application with the best technology.

Nitrogen Membrane

Listed below are Nitrogen Generator Systems we offer:

Generon IGS offers a complete line of Nitrogen Membrane Generators for applications requiring purities between 95% and 99.5% Product Nitrogen. All systems can be custom designed to meet your needs and the stringent demands of the Oil & Gas Markets.

- Nitrogen Membrane Cabinets

- Nitrogen Membrane Skidded Systems

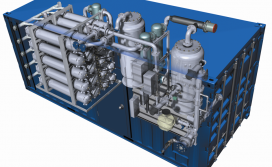

- Nitrogen Membrane Containerized Systems

- Nitrogen Membrane Integrated Packages

- Nitrogen Membrane Mobile Units

- Nitrogen Services Rental Equipment exclusively through Global Nitrogen Services

Generon IGS, Inc. has been supplying GENERON gas separation membranes since the mid 1980’s. With a track-record of reliable and efficient membranes and our experience in the design of gas separation and purification systems, we work closely with OEM’s and System Integrators to add value to their customers.

Generon IGS controls all aspects of its proprietary and patented hollow-fiber manufacturing process: From formulation, to extrusion, to process treatment, to spinning, to post treatment, and ultimately to fabrication of the Gas Separation Membrane Modules. Painstaking QC and years of experience in the design and fabrication of membrane fibers, membrane modules and systems enables the GENERONÒ fiber to be the standard of the industry.

The foundation of Generon’s technology stems from Dow Chemical’s Polymer Research Group, which screened hundreds of polymers in the 1970’s and 1980’s before selecting the optimum combination of gas permeability and selectivity. This work has allowed Generon to lead the industry in the delivery of high productivity nitrogen solutions for over 20 years.

Generon holds 15 patents covering the process of converting the polymer into hollow fibers about the size of a human hair. Specialized technology is required to balance fiber strength and gas flow characteristics to optimize fiber performance.

Generon holds 20 patents covering the technologies used to bundle our polymeric fiber into completed modules. Each module has up to 1-million or more fibers and it is critical that each fiber be bundled in a way that insures that each fiber contributes to the gas separation process.

Our technology development over the past twenty years has improved membrane separation efficiency by 500%! Generon’s R&D efforts are continuing to broaden the number of applications and improve performance today and in the future. Generon not only supplies membranes for the separation of Nitrogen from air, but also various gases like CO2 (CO2 from Natural Gas, CO2 Rejection, CO2 Recovery), Hydrogen (H2 Recovery), Syngas (H2:CO-Ratio Adjustment), and Biogas (CO2 Removal, Gas Dehydration).

Nitrogen PSA

High Purity Nitrogen Generators - Purities from 95% up to 99.9995%

Generon IGS, a leader in the design and manufacture of air separation systems, offers a complete line of Pressure Swing Adsorption (PSA) Nitrogen Generators to compliment its Membrane Technology Line.

To maintain its leadership position, Generon IGS continually researches new design technology in its PSA product line to meet our customers' requirements. Energy costs are the main part of the operation of a PSA nitrogen generator. Generon IGS has dedicated special attention to this issue and has optimized the PSA process in order to make the NITROSWING® PSA Nitrogen Generator the most efficient product currently available on the market.

The PSA product line offered by Generon IGS constitutes one of the largest available to suit almost any application and specific requirements to produce gaseous Nitrogen. These range from standard Industrial applications to highly specialized units for harsh and hazardous environments. Units range up to hundreds of thousands of cubic feet per hour, from 95% to 99.9995% Nitrogen Purity. Our product lines can also be configured for CRN, CSA, CE and or PED requirements; as well as to specific customer specifications.

Generon IGS PSA product lines are the most extensive in the market. Product line includes:

NITROSWING - Compact PSA Nitrogen Generators – The system integrates both Air and Nitrogen buffer tanks on the same skid as the generator.

NITROSWING Twin Tower PSA Nitrogen Generators – Our standard Twin Tower PSA systems set market standards in product quality and efficiency.

NITROSWING - Sequential PSA Nitrogen Generators – The system integrates multiple adsorber beds on a common skid to maximize flow in less space than a conventional PSA system.

Generon PSA's can be standard or engineered systems, fully tested prior to shipment.

Generon IGS Nitrogen PSA Generators:

- Purities up to 99.9995% (5 ppm of residual nitrogen)

- The only manufacturer to offer several PSA configurations to the market

- Reliability of operation second to none

- Your own independent on-site supply of nitrogen and freedom from the ever escalating costs of nitrogen from industrial gas suppliers

- Savings of over 50% compared to traditional industrial gas supply methods

- Ability to custom design our larger nitrogen generator plants to your specific requirements

Nitrogen Mobile Unit

Our custom designed Truck & Trailer Combo Series will allow for a dramatically more compact and mobile membrane systems. The key to this new product line is maximum mobility by combining air supply, membrane nitrogen generation and nitrogen booster compression and then to install it all on one truck that is easily operated. Where other membrane systems and inert gas generators require multiple transports and long setup/breakdown times, our Combo Series is already mounted on a single trailer, interconnected, calibrated, and ready for operation.

Complete systems are packaged in our Houston ISO 9001:2000 - certified fabrication shop to meet your exact requirements. To handle your short-term needs, IGS maintains an extensive fleet of mobile nitrogen generators for rental through Global Nitrogen Services.

Using the patented Generon® membrane, we offer the lowest cost Nitrogen production on the market today. The actual air separation process takes place in the nitrogen membrane modules.

- Custom-Built

- Truck Or Trailer-Mounted

- Fully-Integrated With Primary Compression And Booster Capabilities

- You Pick The Truck, Engine And Options

- Your Exact Specifications

- Nitrogen Purities From 90-99%, Systems Include Fully Automatic Nitrogen Purity Control

- Equipped With Certified Oxygen Analyzer

- Nitrogen Flow Meters For Accurate Monitoring And Control

Truck or Trailer Mounted Nitrogen Generation Systems

| Feature | U.S. Standard | S.I. Standard |

| Truck Unit | 500 scfm to 1500 scfm | 14 Nm3/hr to 42 Nm3/hr |

| Trailer Unit | 500 scfm to 3000 scfm | 14 Nm3/hr to 85 Nm3/hr |

| Supply Pressures | 200-500 psig standard | 13.7 bar g to 34 bar g |

| Booster Capabilities | Up to 5000 psig | 345 bar g |

| Nitrogen Dew Point | -70 degrees F | -57 degrees C |

Marine Systems

Generon IGS is the world’s leading supplier of Non-Cryogenic Membrane Systems to the Maritime Industry. Generon provides both PSA and Membrane technologies to meet the stringent demands of the Marine Industry.

Since 1987 Generon IGS has supplied On Board Nitrogen Solutions to more than 1,000 ships worldwide.

Our systems are designed to meet any third-party registration, with proven field reliability, covering a wide range of flow capacities, nitrogen purities and footprint variances.

Generon can provide stand-alone units or completely integrated turn-key systems for New Build or Retrofit purpose.

With Generon’s in house membrane research and development capabilities the offering to the Marine industry has undergone tremendous improvements for energy and footprint savings.

All systems are manufactured and tested at the Generon facility in Houston, TX. To inquire about a Nitrogen Generator designed for the Marine Market.

TYPICAL MARITIME APPLICATIONS FOR GENERON SYSTEMS INCLUDE:

- Cargo Hold Inerting/Oxidation Control

Our systems provide the highest level of safety and security for your valuable cargo. Whether your cargo is flammable, explosive, or oxidizes, Generon’s systems will get it to port.

- Transporting Perishable Goods

Our extensive experience in Controlled Atmosphere and Modified Atmosphere transport of fruits, vegetables and many other perishable goods ensure that they arrive to market ready to eat.

- LNG/LPG

Generon membrane systems meet the rigorous requirements for transportation of these products with purities to 99.9% and dew points to -80°C. Custom designs to meet any classification.

- Cargo Hold and Hull Fumigation

Purging of cargo hulls and holds to eliminate bugs and microorganisms, preventing contamination of local waterways.

- FPSO (Floating Production, Storage and Offloading Systems)

With considerable experience of marine standards, classification requirements and petroleum industry standards, GENERON is able to supply our membrane technology to FPSO vessels. The use of such vessels for the recovery of offshore oil and gas is growing.

Industrial Nitrogen

Generon offers both PSA and membrane type systems to the industrial markets.

Containerized Nitrogen Units

Thermo Fisher Scientific | Diteco | Dosch | Hoffer | Airtek Saimo | Tectron

Master Mag | Igs | Titan | Gea Phe | Inox | Centec | Sodern