|

|

Principal Products

- AIRTEK

- CENTEC

- DITECO

- DOSCH

- H E - TITAN

- HOFFER Turbine Flowmeter

- IGS

- INOXCVA

- MASTER MAG

- PHE- GEA

- SAIMO

- SODERN

- SYSCO

- TECTRON

- Thermofisher Scientific

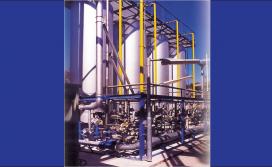

Process Gas Systems

Membrane and PSA based technologies are used for gas separations (CO2, H2S and water removal from conventional, shale and biogas, hydrogen purification, helium purification and more).Generon’s core focus has been in the air separation industry, providing nitrogen and oxygen generators, using PSA (pressure swing adsorption) technology since the 1970’s, and the patented and proprietary membrane technology, developed by Dow Chemical in the 1980’s. Since then, continuous improvements of Generon’s technologies has led to over seventy-five (75) patents and a wider range of applications.

Today we are offering not only the best-in-class on-site air separation systems (as direct sales, lease-to-own or rental), but also non-air / process gas separation systems. Those process gas separation systems are membrane and PSA based and find their applications in the natural / bio gas industry and the refinery / petrochemical industry as well as other basic industrial manufacturing processes. Generon prides itself in providing complete solutions to its client. We provide detailed engineering and designs, custom fabrication, as well as process guarantees on all our systems. We also provide after sales and service support for maintenance and spare parts.

Generon offers superior quality, high efficiency, cost effective systems. The systems are custom designed and fabricated in the Houston, TX facility, while the membrane is fabricated in the Pittsburg, CA facility. The facilities are ISO 9001:2008 certified. In addition to providing PSA and membrane systems, Generon also packages gas compressors, blowers and manufacturers pressure vessels.

We are able to meet our client’s needs, whether it is for natural gas treatment to meet pipeline gas or fuel gas specifications or hydrogen or helium recovery systems requiring ultra pure product gas. To inquire about our process gas systems

Features such as simple operation, proven reliability, minimal space requirements, and low cost have made Generon the preferred vendor for many major applications.

CO2 REMOVAL SYSTEMS

FUEL GAS CONDITIONING SYSTEMS

HYDROCARBON LIQUIDS RECOVERY

H2S REMOVAL SYSTEMS

GAS DEHYDRATION SYSTEMS

BIOGAS TREATMENT

COAL BED METHANE TREATMENT

HYDROGEN RECOVERY

SYNGAS H2:CO RATIO ADJUSTMENT

HELIUM RECOVERY SYSTEMS

FLUE GAS TREATMENT

SF6 RECOVERY SYSTEMS

Thermo Fisher Scientific | Diteco | Dosch | Hoffer | Airtek Saimo | Tectron

Master Mag | Igs | Titan | Gea Phe | Inox | Centec | Sodern