|

|

Category Products

- ENGINEERING SYSTEM

- Analyzers

- Measurement

- Bulk Handling System

- Heat Exchanger

- Air Separation

- Water Treatment

- Valves & Actuators

- Others

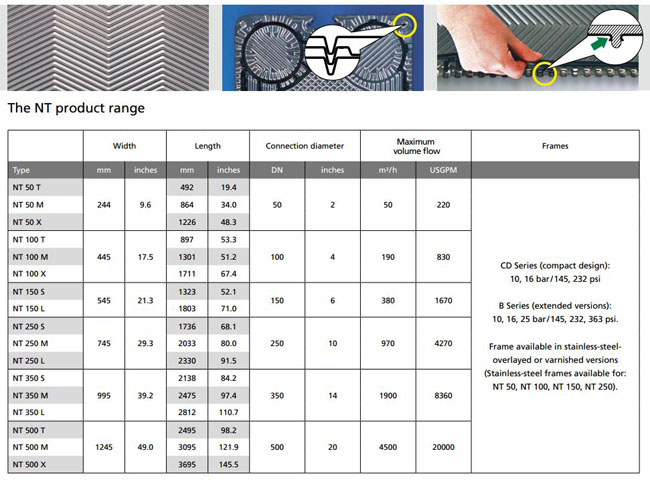

GEA - Plate Heat Exchanger

The new plate heat exchanger generation

Higher performance, more applications and even less investment: the new versa-tile NT Series fulfills the requirements of the industry and sets economical standards for future plate heat exchangers.

Higher performance– an optimised plate design which enables your wishes to come true, in that higher heat transfer can be achieved with less surface area. This simply means: less investment.

More applications– a universal plate program creates flexibility, through which your requirements can be realised even more accurately.

Quicker maintenance– new gasket & attachment technology making servicing easier and providing a firm, perfect fit of gaskets and plates.

The NT Series offers every plate type in various lengths and profile variations that ensures an accurate answer to any requirement.

Your advantages at a glance

- high heat transfer rates

- low investment and service costs

- optimised distribution of media

- high pressure resistance

- simplified handling

- quick and safe gasket replacement

- flexible solutions for special requirements

- non-standard materials available

- leading manufacturer’s know-how

Features and advantages

OptiWave-design

The optimised corrugation leads to a good fluid distribution across the whole plate width. This leads to the highest heat exchange rates being achieved with the lowest pressure drop.

PosLoc-fixation

With the new NT Series, we have introduced a self-centering plate system. The result being a stable, perfectly aligned plate pack, with the gaskets lying directly above each other leading to a longer lifetime.

EcoLoc-gasket system

The new, glueless EcoLoc gasket ensures a quick and uncomplicated exchange of gaskets.

GEA PHE Systems – Competence in Heat Transfer

With emphasis on the highest quality standards and constant innovations, GEA PHE Systems continues to expand its market position: Within the GEA Process Equipment Division, GEA Ecoflex together with GEA ViEX, GEA WTT, GEA Ecobraze, GEA PHE Systems NA and GEA EcoServe forms GEA PHE Systems, the Center of Competence and Service Center for gasketed, fully welded and brazed plate heat exchangers of GEA Group:

- HVAC

- Refrigeration

- Sugar

- Chemical

- Paper

- Food

- Power

- Marine

- General Industry

- Renewable Energy

- INQUERY

- DOWNLOAD

Inquiry GEA - Plate Heat Exchanger

File to download not found

Thermo Fisher Scientific | Diteco | Dosch | Hoffer | Airtek Saimo | Tectron

Master Mag | Igs | Titan | Gea Phe | Inox | Centec | Sodern