|

|

Principal Products

- AIRTEK

- CENTEC

- DITECO

- DOSCH

- H E - TITAN

- HOFFER Turbine Flowmeter

- IGS

- INOXCVA

- MASTER MAG

- PHE- GEA

- SAIMO

- SODERN

- SYSCO

- TECTRON

- Thermofisher Scientific

GEA PHE Chemical

Concentrating on competence – for your benefit

Within the GEA Process Equipment Division of the international GEA Group, GEA PHE Systems is responsible for plate heat exchanger technology. Strong individual companies: GEA Ecofl ex, GEA ViEX, GEA WTT, GEA Ecobraze and GEA PHE Systems NA with production locations in Germany, Sweden, the USA, Canada and India produce gasketed, fully welded and brazed plate heat exchan-gers for worldwide distribution for use in almost all industrial applications. GEA EcoServe – the GEA PHE Systems service organisation – operates customer service centres in many countries to provide a rapid and competent maintenance and spare parts service, all around the world.

because the chemistry must be right

Despite the fact that many processing techniques in the chemical industry have under-gone major changes, fundamental problems have remained. These include the targeted heating and cooling exchange during the production process. Increasing emphasis is placed on this area within the framework of technical and economical optimisation, requiring specifi c engineering advice and high performance components. As one of the pioneers in the development of plate heat exchangers, GEA PHE Systems offers state of the art technology, irrespective of whether you are active in the manu-facture or processing of chemical or petrochemical products. Being an important link of your production chain with regard to your productivity, profi tability and competitive-ness, we ensure reliable function and high performance.

Application for all products

- Basic chemical fl uids

- Petrochemical products

- Special chemicals (adhesives, lacquers, etc.)

- Life science products (pharmaceutical, etc.)

- Consumer products (cosmetics, cleaning agents, etc.)

Tailor-made – yet customised

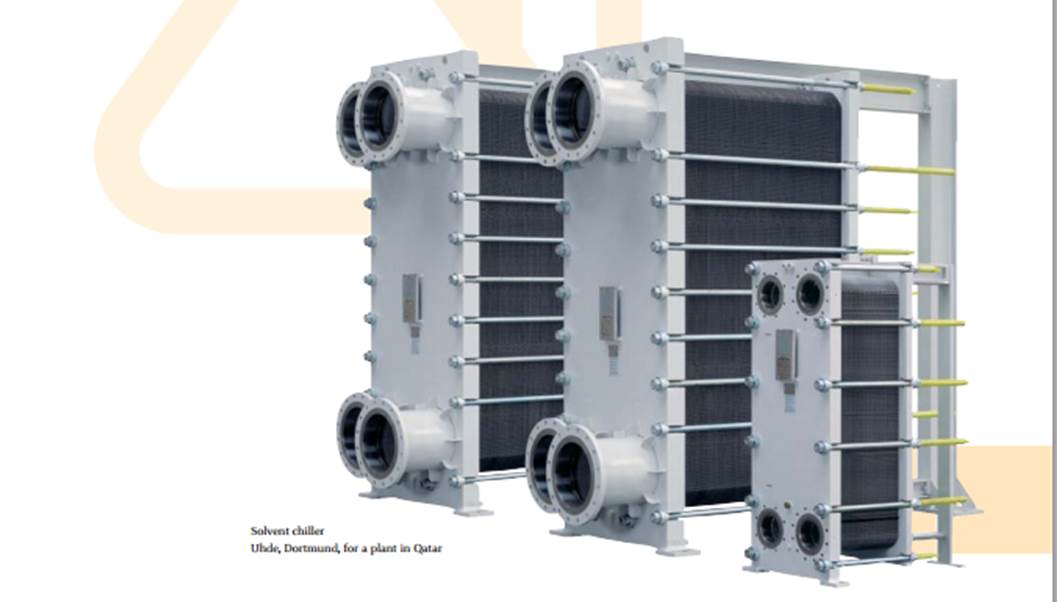

Based on many years of experience, we are able to develop individual solutions for you in your particular fi eld with a maximum of functional reliability. GEA PHE Systems understands itself as a system advisor and not exclusively as a supplier of products. Whatever your chemical fi eld may be: We will provide you with personal advice during your planning phase, which also includes start-up / commissioning and future maintenance. All-round consultation and service – you should not content yourself with less. GEA PHE Systems equips sulphuric acid plants world-wide, e. g. in Spain, Bulgaria, Algeria and South America. Furthermore our plate heat exchangers are installed in fertilizer production sites, e. g. in projects of Uhde

Deutschland for:

- Sorfert (Algeria)

- EAgrium, MOPCO, HFC, EFC II, Alexfert (Egypt)

- QAFCO (Qatar)

A solution implies multiplicity

Whatever medium is employed, GEA PHE Systems can offer the suitable plate heat exchanger for you. This means that the basic principle of EcoFlex (gasketed) and EcoWeld (fully welded) plate heat exchangers is varied by means of different materials and channel geometries and precisely matched to the media. Chill water, fabricated plastic products, lye, petrochemical products and acids count among the typical examples. This ensures optimum material selection of your product, entirely in the sense of function and durability.

Wear resistant plates

As between humans, the chemistry also has to be right for the media and the materials. The plates are, for instance, made of stainless steel according to different standards, or special metals, such as Alloy 59, 686, C 276, Incoloy, Nickel, Tantalum, Titanium, and Titanium / Palladium.

Durable gaskets

Materials such as NBR, EPDM or FPM have proven themselves in the same way as the sealing techniques. GEA PHE Systems offers two techniques: EcoLoc or LocIn, both without the use of adhesives to simplify maintenance, or with adhesive for special applications. A full length and secure seal holder prevents the media from intermixing – also in the leak collection compartment.

High resistant profi les

The viscosity and the portion of solid bodies in the medium as well as the required fl ow dynamics and heat transfer determine the channel geometry of the plate heat exchangers. Here, GEA PHE Systems meet precisely every technical production requirement with utmost care.

Thermo Fisher Scientific | Diteco | Dosch | Hoffer | Airtek Saimo | Tectron

Master Mag | Igs | Titan | Gea Phe | Inox | Centec | Sodern